基础第一:安装在scapoose, OR脱水厂基础

INDUSTRY

Construction

EQUIPMENT USED

- Excavator

- 10K reach forklift

- 60M concrete boom truck

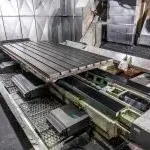

某大型混凝土和骨料公司的疏浚脱水系统 Scappoose, OR, had been in the same location for several years, 但疏浚活动在该系统周围形成了一个半岛. As a result, 该公司需要将他们的整个业务转移到半英里外,以保持靠近活动, yet out of the projected dredge path. They had planned this relocation for October, during a scheduled plant shut-down, 但是在主要系统部件澳门威斯人平台首页之前,他们需要安装一个巨大的混凝土基础.

他们开始寻找一家可靠的磨坊公司,可以处理这个项目的规模和范围. After providing a drawing set to our Portland-based millwright team 收到澳门拉斯平台首页的报价后,欧米茄澳门威斯人平台首页被授予这个项目. 澳门拉斯平台首页有两周的时间来计划安装,四周的时间来完成 industrial millwright services team got to work.

MILLWRIGHT SERVICES FROM THE FOUNDATION UP

Planning began with an initial site survey, 这让澳门拉斯平台首页更好地理解了这个项目的规模——500平方码,是澳门拉斯平台首页团队迄今为止建造的第二大地基. The challenge that comes with a foundation of that size is scaling; the steps for installation remain the same as a smaller foundation, 但成功的完成必须考虑到额外的时间和工作人员,同时将任务分成可管理的部分.

Our millwright crew 制定了一个战略计划,包括两个混凝土浇筑-一个用于较低的主垫,另一个用于机器基座. 工作人员还在规划过程中预先建造了木制形式面板,并购买了必要的30块,000-pound rebar package. 执行该计划需要有限的设备:一台用于清理和回填的挖掘机, a 10,000-pound reach forklift to handle the material, and a 60M boom truck to place the concrete.

INDUSTRIAL MILLWRIGHTS AT YOUR SERVICE

在四周内完成安装和300立方码的混凝土放置, our team of four millwright technicians assembled. 前5天进行了区域挖掘和设置巨大基础的碎石回填支护. Next, Omega Morgan的木工团队将木制面板放置到位,并安装了30个中的大部分,000 pounds of rebar within the framework over four days. 当浇筑混凝土的时候,又有六名磨坊工人加入了这个团队. Together, they made quick work of pouring, spreading, and smoothing the main concrete pad in one day, prior to tackling the machine pedestals. 然后,澳门拉斯平台首页的工作人员在主基础顶部形成每个机器基座,然后安装钢筋,并在剩下的六天内完成第二次浇筑. 最后,澳门拉斯平台首页剥去表单,露出成品.

In October, with the new machinery foundation installed on schedule, 欧米茄澳门威斯人平台首页帮助完成了工厂的机器搬迁. 澳门拉斯平台首页的客户对澳门拉斯平台首页完成项目的速度表示赞赏, as well as our attention to detail throughout the process. This project is another example of our industrial millwright crew doing the impossible daily.